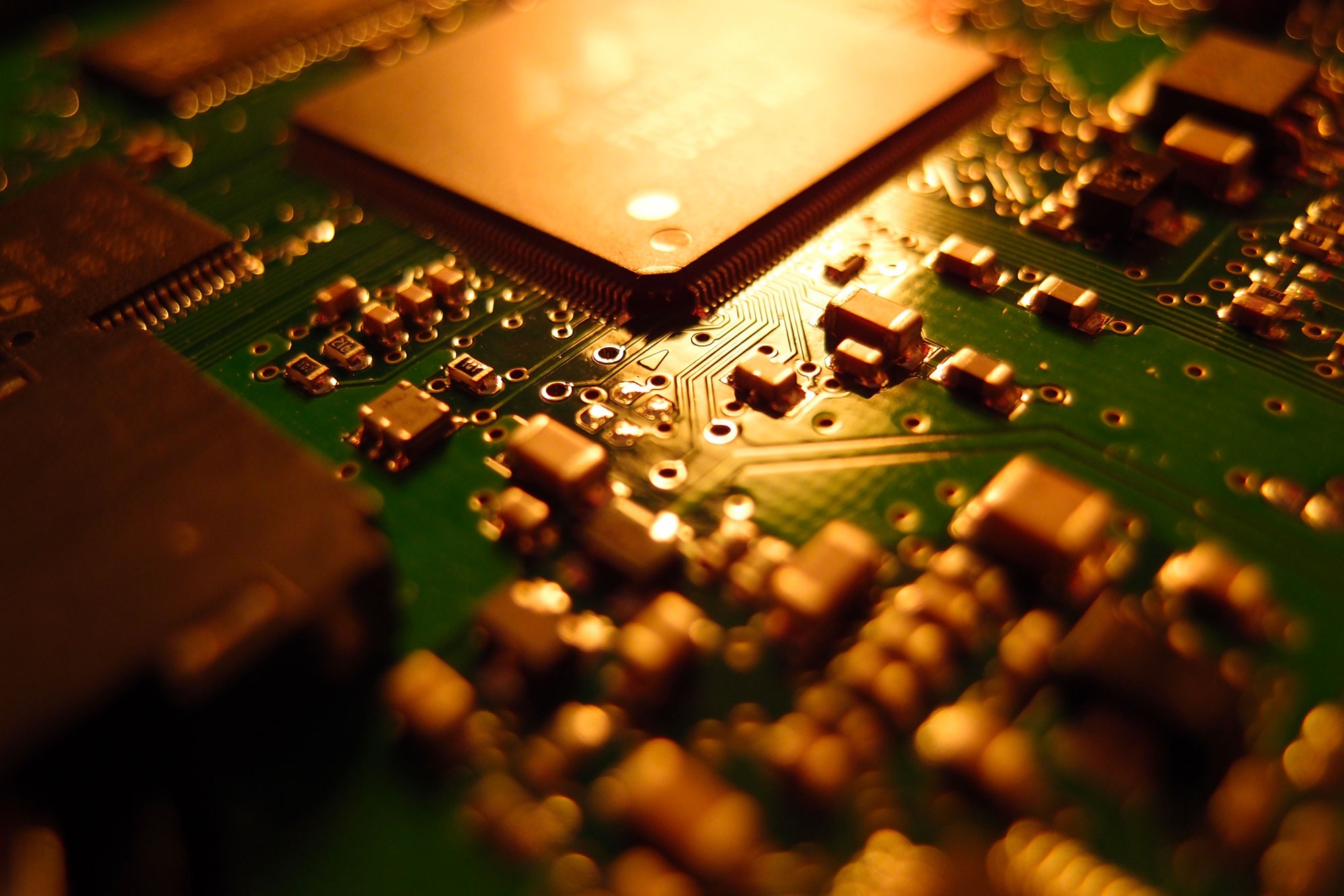

Receptacle

When using test machines, the receptacle is an important component, not only because it is the element that supports the Spring Contact Probe, but above all because it allows for their quick and correct replacement, without the need to modify or disassemble the test machine.

According to functional needs, Spring Probe can be inserted or screwed into the receptacles, and to do this you need suitable connectors and accessories that we, at Tecon, design and build tailored to the type of receptacle.

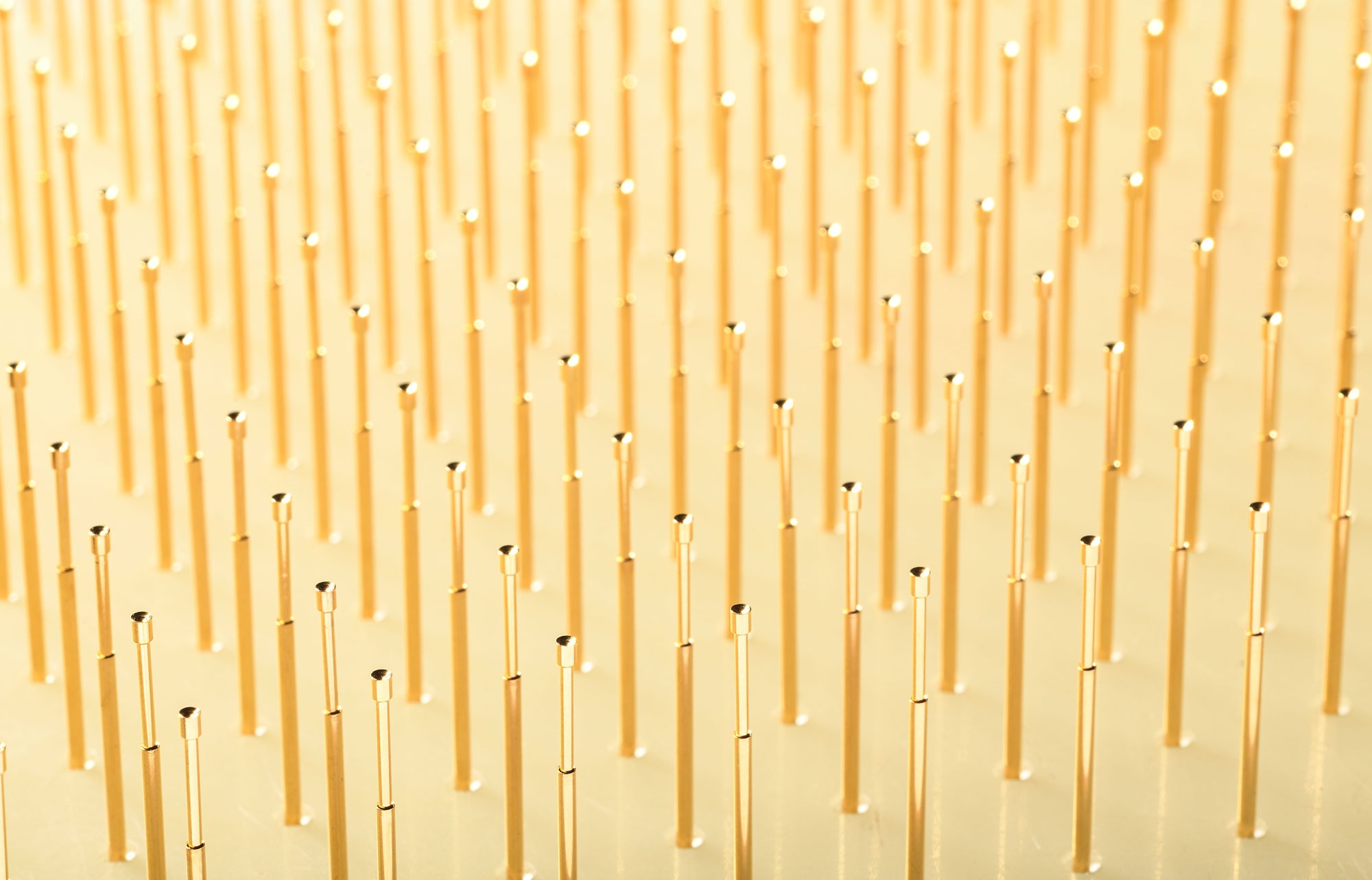

How are the receptacles made?

- With collar: the receptacles with collar can be inserted into the fixture with a fixed value and guarantee precision in the height of the receptacle;

- with swelling: the swelling during the installation of a receptacle is used as a stop, or to create interference in the housing hole.

If, on the other hand, the swelling is used to create interference, it will be possible to insert the receptacle at different heights in the fixture.

At Tecon we are able to supply various swellings to heights required by the customer.

- Retaining fingerprints : they represent an extra security to ensure that the Spring Probes do not come out of the receptacle. Being “notches” that are made on the receptacle and that allow to create a rubbing surface between barrel and receptacle, they guarantee the perfect union between them;

- thread (threaded): in particular applications, especially in the automotive industry, individual receptacles and Spring Probes are created with a thread that allows to have the absolute certainty that the probe does not comes out from the receptacle.

How do receptacles work?

There are different methods to connect the receptacle to the electronics of the test machine by wires:

Solder

this system consists in welding the wire of the test machine to the dedicated seat on the receptacle, ensuring excellent electrical contact and easier replacement of the receptacle. It is often used in the presence of low density Probe

Crimp

this system consists in crimping the wire of the test machine inside the dedicated hole on the receptacle. It is used in cases of high density of receptacles, small Probe sizes or where, due to the limited space available, it is not possible to use the Wire-Wrap system

Wire-Wrap

this system consists in winding the wire of the test machine on the square termination of the receptacle. It is often used for the speed that the connections could reach thanks to the approved instruments

Round Post

this system consists in inserting the round termination of the receptacle directly into a dedicated seat on the test machine.

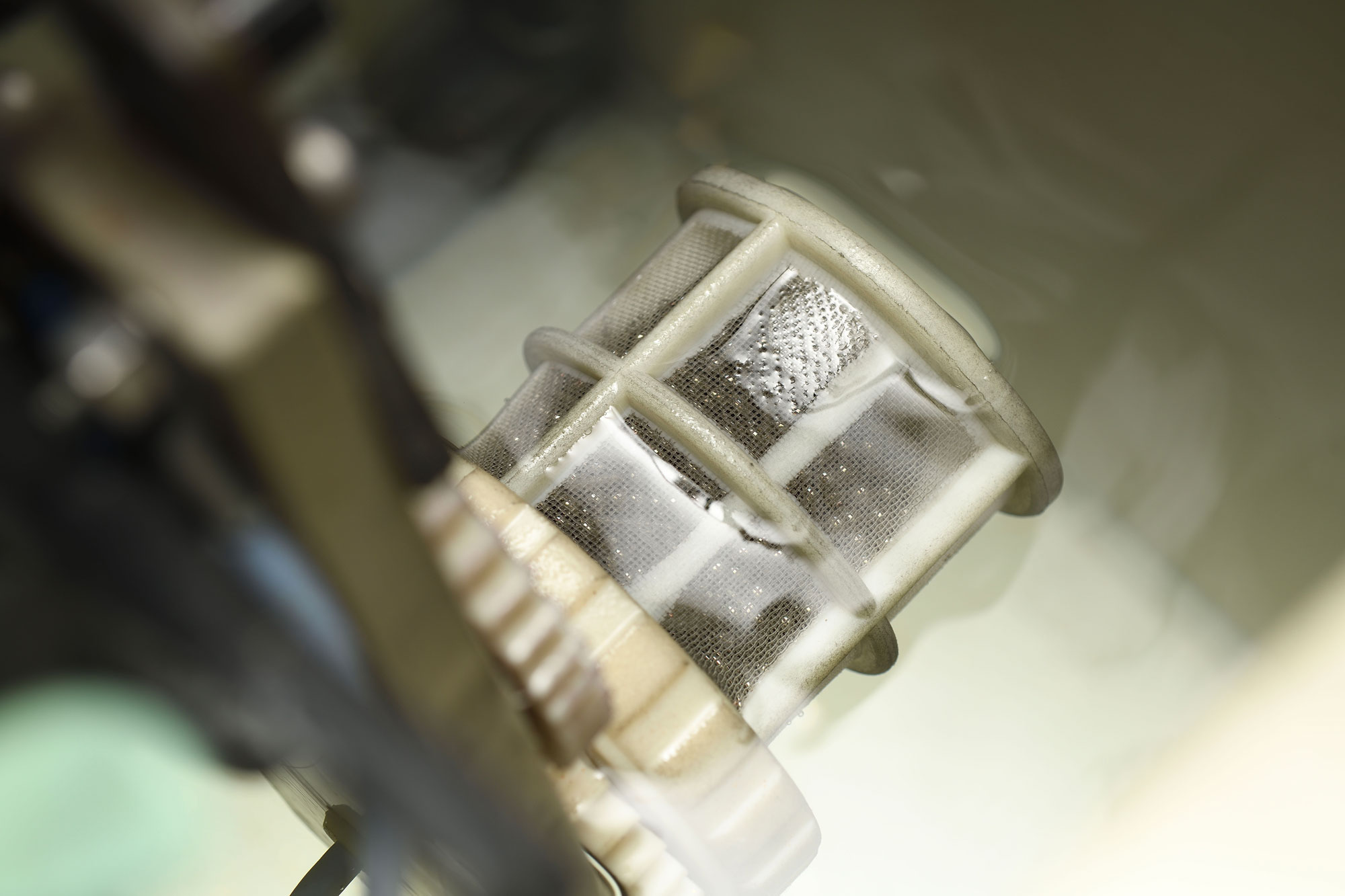

How are receptacles mounted?

Before proceeding with the assembly it is very important that the holes present on the fixture are accurately executed, this is the only way to guarantee that the receptacles are correctly positioned.

To reach this condition and ensure our customers a job well crafted in every detail, we have specified which drill bits to use to make our receptacles on our catalog, keeping in mind that the drilling is always influenced by the type of material, the drilling rounds, the type of tip and the shape itself.

Finally for each article, we produce specific insertion and extraction tools, useful for inserting and extracting receptacles from the fixture.