Technical characteristics

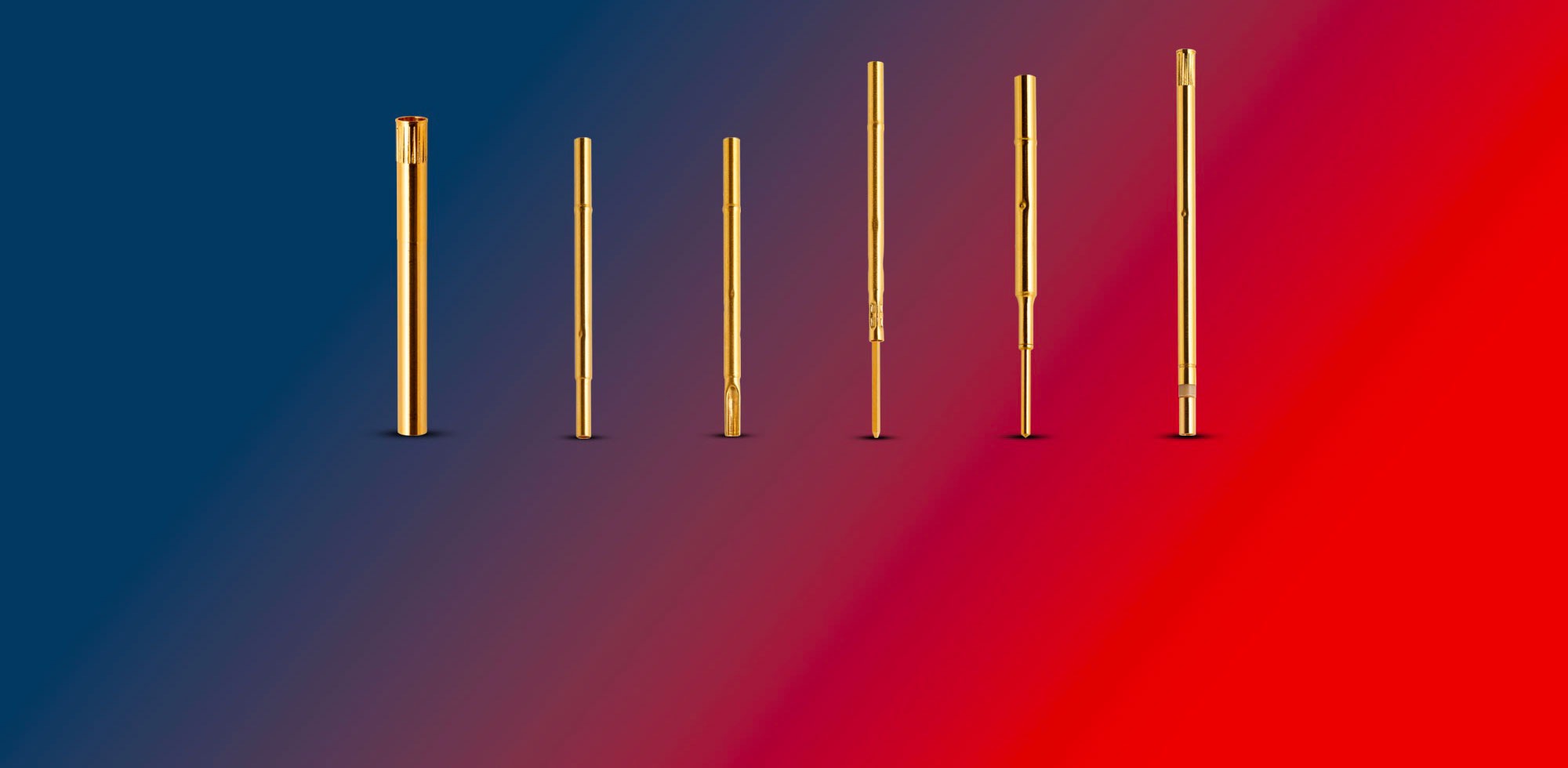

The functioning of a Spring Probe depends on the quality and workmanship of the three main parts that compose it (barrel, spring and plunger). Its design, on the other hand, varies according to each individual need and for each specific electrical circuit.

Spring probe barrel

The barrel is used to contain the spring, and the plunger travels through it. It’s the most solid element. It extends in length and, depending on its function, has various diameters. It can be produced in brass, bronze or nickel silver.

The characteristics of each material can be read here.

Each Spring Probe can have a different size and diameter of the barrel, according to our customer’s needs, but it must have the right size for the perfect coupling with the receptacle. This is the only way to be able to replace the Test Probe quickly and easily at the end of its life cycle.

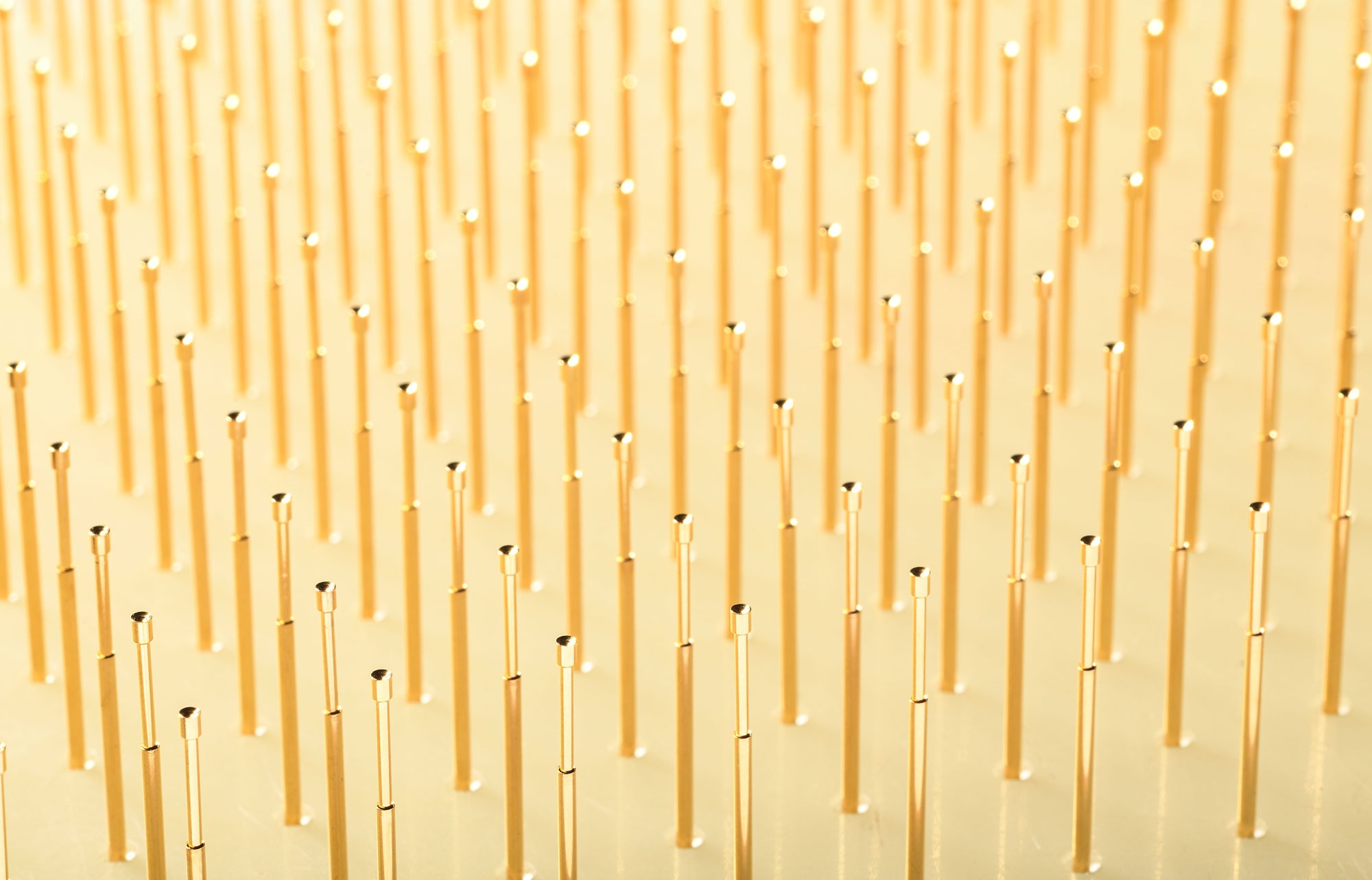

Spring probe springs

The spring of a Spring Probe plays a key role in ensuring good and the right amount of load to be applied on the PCB (Printed Circuit Board). For this reason we at Tecon pay close attention to three aspects:

- the quality of the spring composition material, which guarantees a high number of supportable cycles;

- the heat treatment studied in our laboratories, which significantly improves the duration and performance of these components;

- Gold and silver galvanic plating which improve conductivity, reduce electrical resistance and prevent oxidation.

Materials for springs

Tecon springs are manufactured in three different materials:

- Bronze: it is an alloy that favors low resistance but carries a reduced load;

- Music wire: it is a very hard steel and excellent for the construction of springs due to its consistency and strength;

- Stainless steel: it is very hard and usually used for high currents or where the springs will work in corrosive environments.

Spring load

The load specified during the selection of the Probe will correspond to the operating stroke of the plunger and will increase as the travel increases.

Normally Tecon Spring Probe are produced by making sure that the spring, in restting conditions, is already slightly loaded by providing a so-called preload and ensuring that the plunger is fully at travel point “0”:

- A harder spring will help penetration through the welds on the PCB, but it may leave head marks on the welds or even cause the PCB to flex. It is usually used when the current values to be measured are high;

- A lighter spring can be used where you do not want to leace marks or curvature of the PCB.

Keep in mind that the spring force has a tolerance of ± 20% but it is possible to reduce the value on request.

If you want specific technical advice on your needs, do not hesitate, contact us!

Spring probe plunger

The plunger consists of a “body” and a TIP head. The latter, according to the many forms it can take, adapts to any type of surface that the customer needs to test.

In this regard, we, at Tecon, are able to provide excellent technical advice to help choose the most suitable head for every kind of need.

Materials

The plungers of the Spring Probe Tecon are made:

- in most cases in BeCu which, after an adequate heat treatment, guarantees hardness and precision, as well as excellent conductivity;

- If the customer requires it, for particular working situations, we also use toughenable steel, which provides extreme hardness and durability, especially in conditions of high currents and possible wear.

- We can also produce brass, bronze, stainless steel and plastic plungers of different types.

Processing

All the milling of the heads is carried out in a dedicated department to allow for precise quality control of the finish and customization.

In the galvanic laboratory we perform gold, silver and nickel plating to ensure the lowest electrical resistance and excellent conductivity, as well as to prevent oxidation of the plungers.

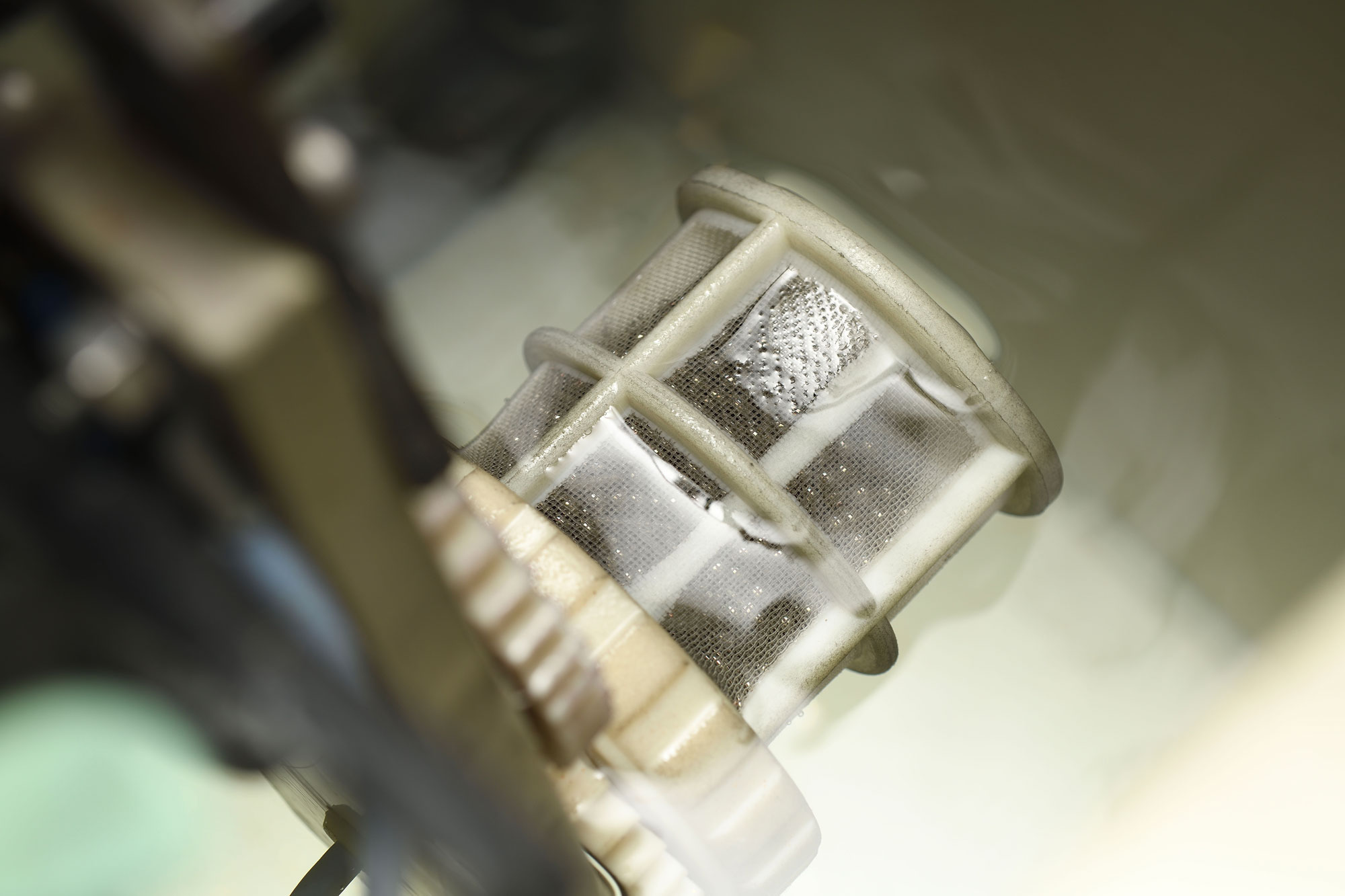

Spring probe coupling mechanism

The good functioning of a Spring Probe also depends on the functional tolerance between the barrel and the plunger. This condition leads to the formation of a “coupling mechanism” of the plunger and then of the head that will go to work on the PCB.

The factors influencing this coupling are the design tolerance, the length of the plunger and the type of plunger guide, single or double. And in the case of very narrow pitch tests, we concentrate our company efforts on working even more accurately.

Being a producer of Spring Probes since 1986 gives us the confidence to exactly define the right tolerances between plunger and barrel. This allows our specialized staff to treat and assemble the Probe in the best possible way in order to drastically reduce the game between the two elements.

We are available to answer any questions, please contact us!

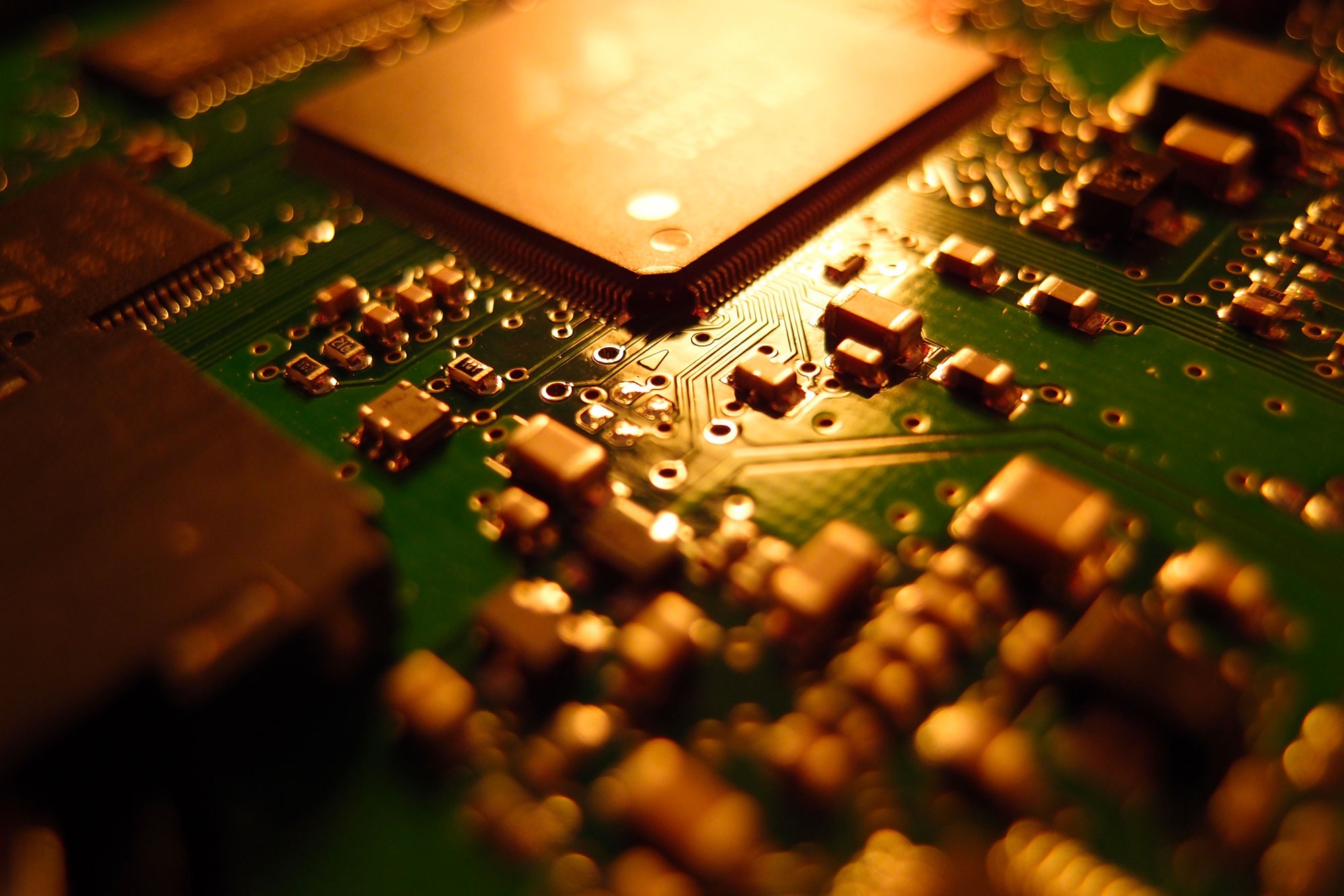

Current path in spring probes

One of the aspects we, at Tecon, pay the most attention to is the study of current flow in a Contact Probe, because it is the main feature for the proper functioning of our products.

In more than 30 years of experience in the sector, thanks to our in-depth knowledge and innovative technologies, we have developed new methods to increase the life cycle of a Contact Probe and to satisfy the customer and his needs.

These are two working contexts we deal with on a daily basis:

- When the current flows through the Contract Probe for a short period of time

The current flows from the plunger through the spring in a very short time and this factor can cause the spring to behave like an electrical resistance, releasing a lot of heat and consequently wearing out quickly.

To prevent this risk, we at Tecon have developed a method to ensure contact between plunger and barrel and consequently between barrel and receptacle, avoiding the involvement of the spring and thus increasing the lifetime of the Contact Probe.

We use our technology to work the plunger milling a part of it, to make the spring work on an inclined plane and force the plunger to clutch on the wall of the barrel This provides greater contact security, even when using springs with very low loads.

- When the high current passes through the Contact Probe for a period of time longer than a few seconds

In order to increase the risk of current passing through the spring, we recommend the use of “through plunger” contacts, such as article GLP503, in which the plunger goes through and is directly welded to the wire.