Quality

Production processes, consulting and machinery

Quality and flexibility at Tecon

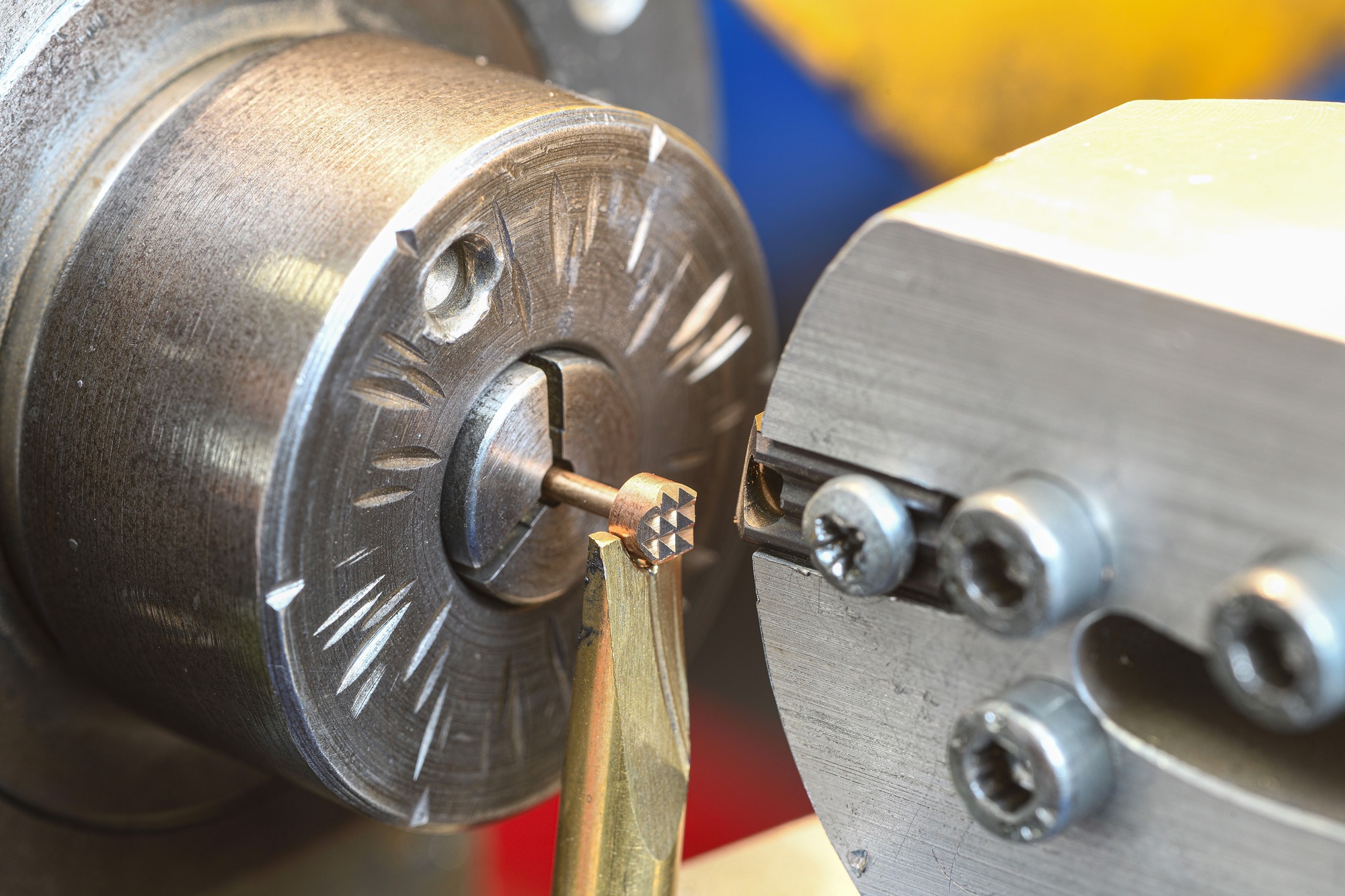

Our company manufactures all products in-house, from the raw material to the finished product. This allows us to have complete control of every single piece and the absolute certainty of its perfection. Below you will find a quick overview of all the production processes, consulting and machinery that Tecon has available to meet the most diverse needs in the field of micromechanics. Starting with the electrical contacts (a sector in which we specialize), our company is able to respond to the production of elements for the most diverse needs and fields of application.