Recommended minimum distance (grid-pitch)

The standard installation pitch for Spring-loaded Interface Contacts is 2.54 mm.

Current rating

The current rating of the spring-loaded Interface Contacts is 3 A.

Typical resistance

The typical resistance of a spring-loaded Interface Contact is 50 mΏ.

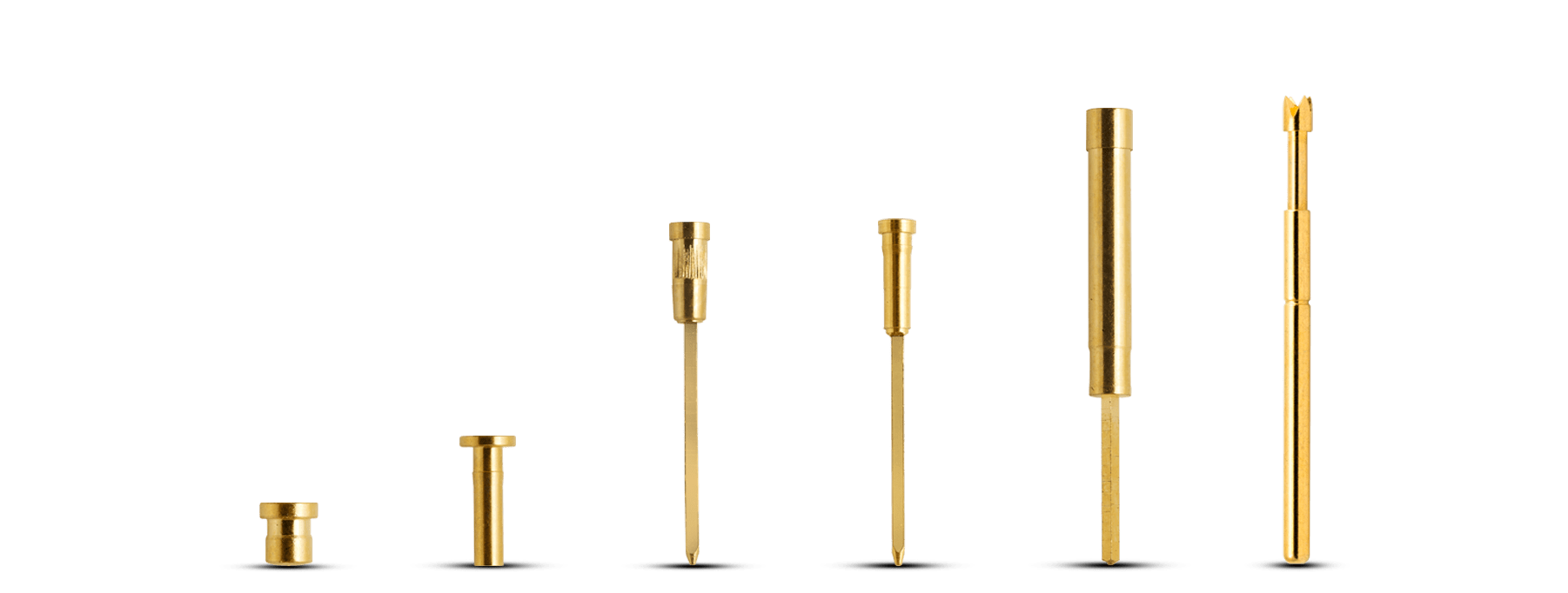

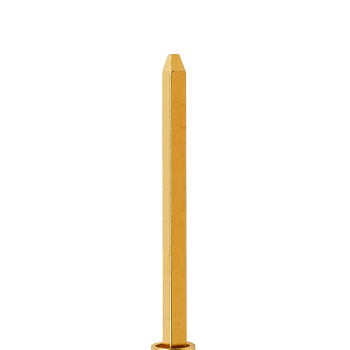

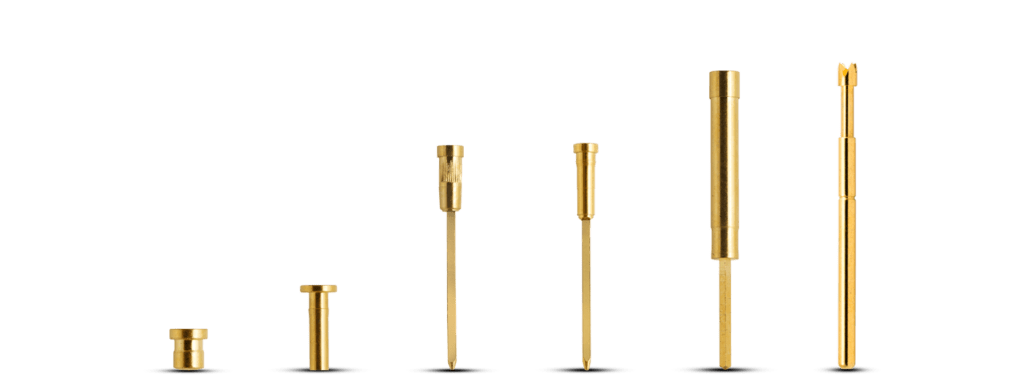

Materials and plating of spring-loaded contact interfaces

The materials used for the production of this type of Interface Contact are:

- for the barrel: bronze, brass or nickel silver. In any case, the galvanic plating treatment is in gold;

- for the spring: music wire then gold plating;

- for the plunger: BeCu (toughenable steel is usually not used because there is no need for a particularly hard material), then gold or nickel-plating.

Receptacle of spring-loaded contact interfaces

For this type of contact the receptacle can be of various types: