The ICT (In-Circuit Test) and the FCT (Functional Circuit Test) allow to detect the main faults that can be found in a PCB (Printed Circuit Board), such as short circuit sor an incorrect component, and to measure the values of resistance and capacity.

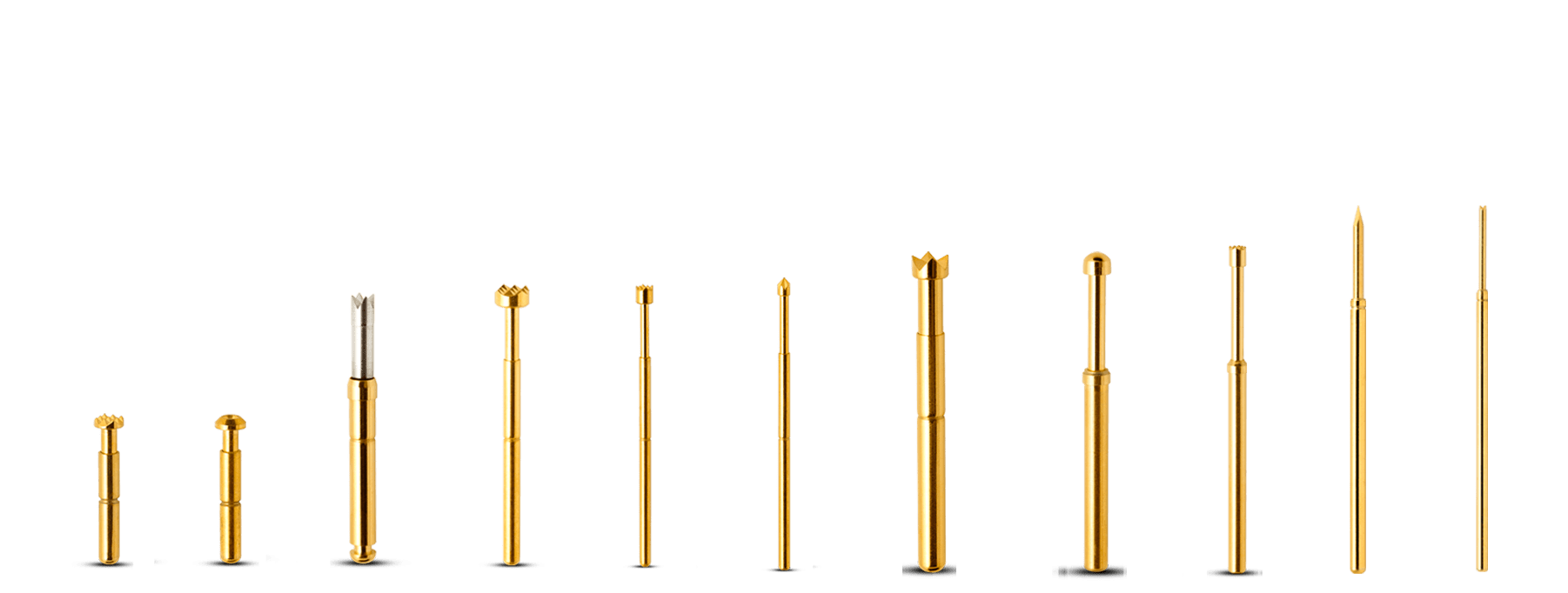

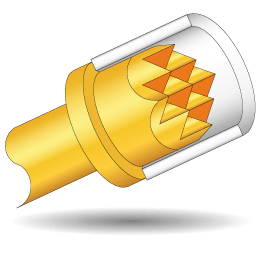

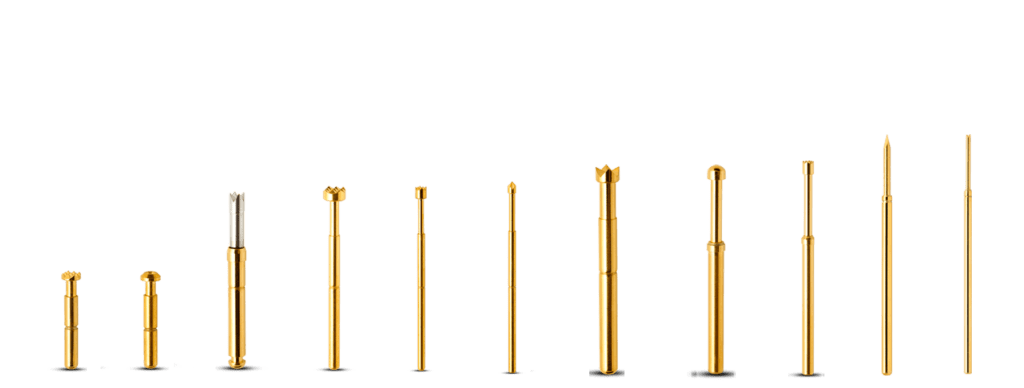

Thanks to the Spring Contact Probe, which connects the DUT (Device Under Test) with the electronics of the test machine, you can solve frequent problems with ease and speed.

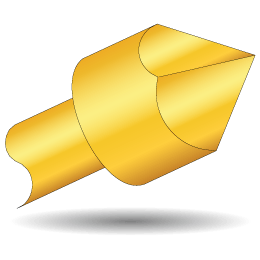

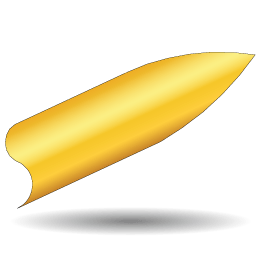

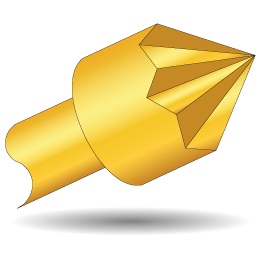

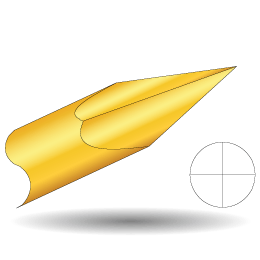

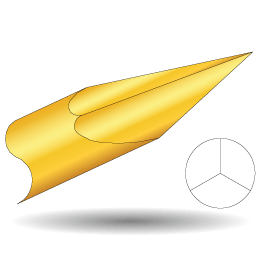

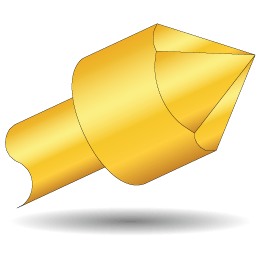

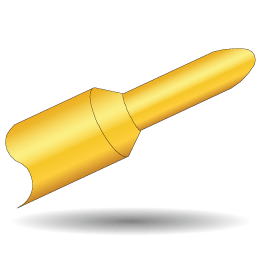

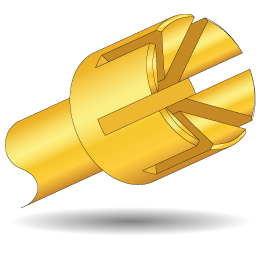

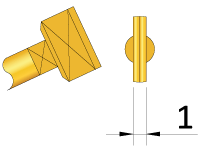

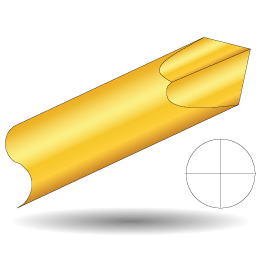

Dimensions, head shape, spring load, construction materials and galvanic finish are the characteristics that make Spring Contact Probe suitable for the various types of surfaces.