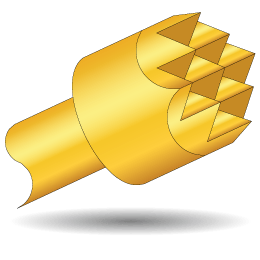

When we talk about high current we never think of the electrical testing sector, where most of the work is done working around 3 Amperes. So the Spring Contact Probes that can work at 5 Amperes are already considered High Current.

The High Current Spring Probe produced by us can work with currents of up to 30-50 Amperes during electrical tests of few seconds duration.

Nevertheless, there are other situations in which Spring Probes can be used, such as in testing equipment that has a longer service life. In this case it is necessary to work on particular technical characteristics that we can develop together with the customer.