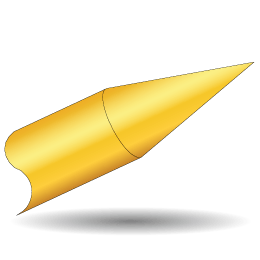

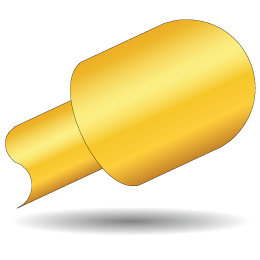

The Double Plunger Probe allows you to create an interface without using soldering. By installing them on special grids and having the mobile part at both ends, they create a connection, for instance, between two electronic boards.

The main feature of these probes is that they have a plunger at both ends.

The two plungers are mounted on the same or on two separate springs; and can be identical or have different head shapes, sizes and lengths.