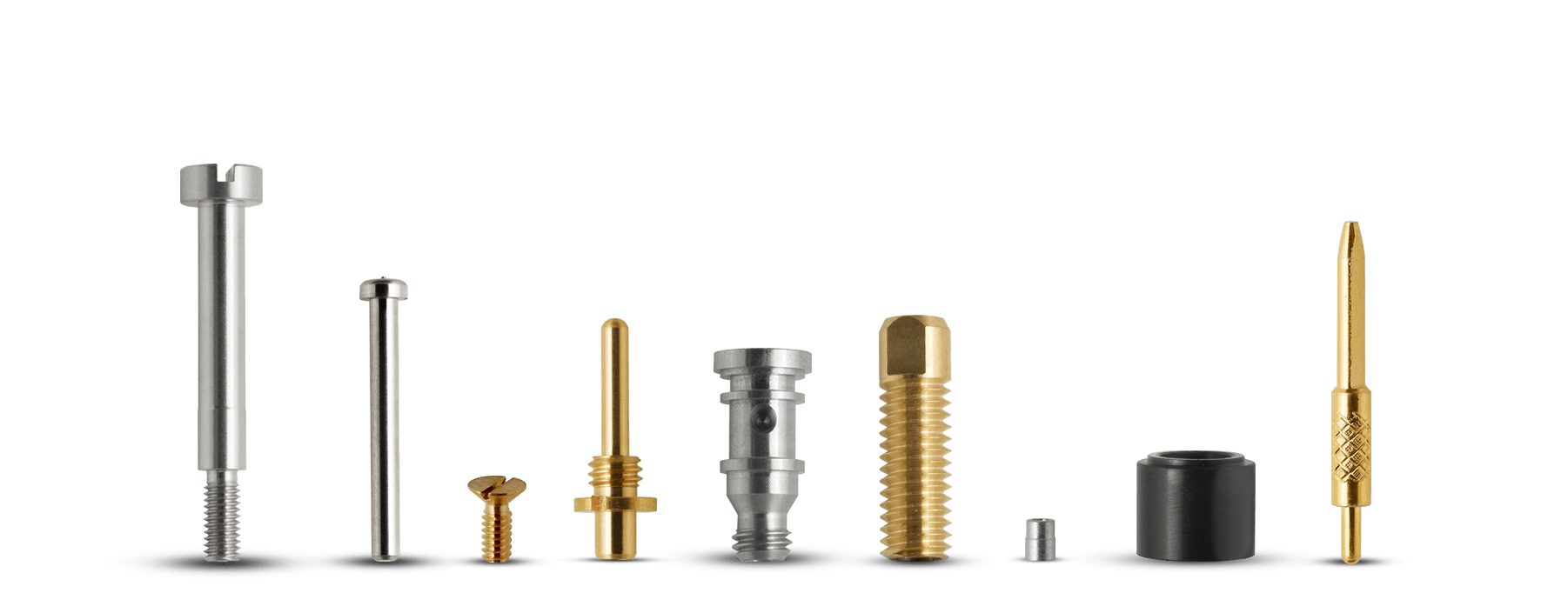

Tecon was born and developed with the aim of producing Spring Contact Probe.

The technology and equipment that we have developed over the years to build all the components of the Spring Contact Probe, however, allow us to also produce many micromechanical parts.

The main areas of use for our parts are medical, high-precision machine development, aerospace, aesthetics and lighting.