In many cases, Spring Contact Probes are not used for ICT/FCT (In-Circuit Test/Functional Circuit Test) processes, but in other applications where there is a need to solder the Probes directly to the PCB (Printed Circuit Board) or to electronic devices without the use of a receptacle.

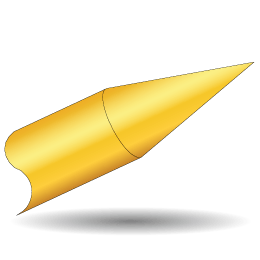

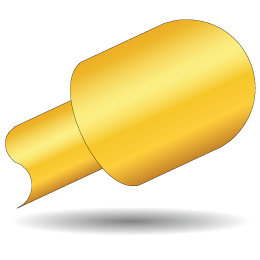

The Solderable Probes were created to meet this need. They are made with a bead for welding at the end of the pipe. They have a hole on the side of the barrel to allow complete cleaning without leaving any processing residue inside it.